Introduction

When working with CO2 lasers, proper ventilation is crucial to maintain a safe and efficient workspace. Laser cutting and engraving produce harmful fumes and fine particulate matter that can pose health risks and damage equipment. A high-quality fume extractor for CO2 laser, an effective dust extraction system, and a reliable laser dust collection setup are essential for any laser workshop.

This guide explores the importance of laser fume extraction, the best systems available, and how to choose the right solution for your needs.

Why You Need a Fume Extractor for CO2 Laser Machines

CO2 lasers vaporize materials, releasing toxic fumes and microscopic dust particles. Without proper extraction, these byproducts can:

Harm respiratory health (causing asthma, allergies, or long-term lung damage)

Reduce laser efficiency (dust buildup can affect beam accuracy)

Damage electronics (corrosive fumes may degrade sensitive components)

A fume extractor for CO2 laser systems filters out hazardous particles, ensuring cleaner air and better machine performance.

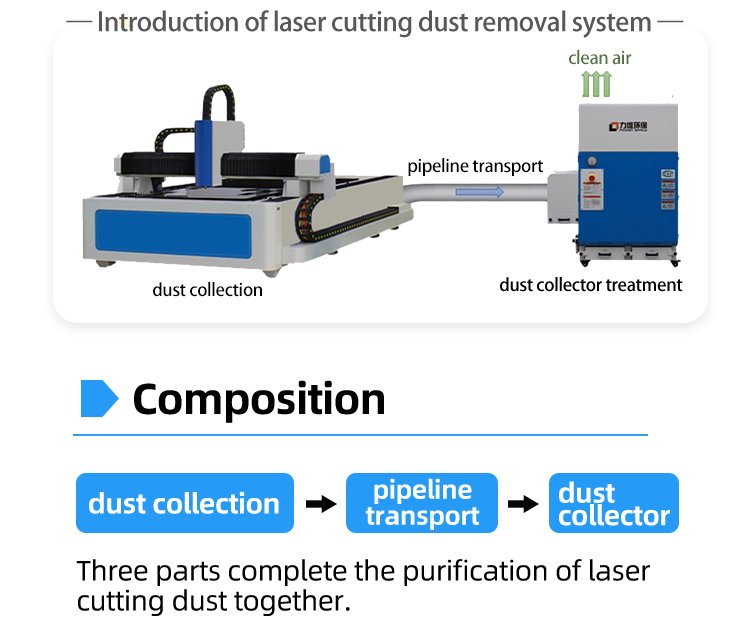

How a Dust Extraction System Works

A dust extraction system captures airborne particles before they spread. Key components include:

Capture Pipe – Positioned near the laser to collect fumes at the source.

High-Power Fan – Generates suction to pull contaminants into the filtration unit.

Filtration Media – HEPA filters (for fine particles) and activated carbon (for gases).

Exhaust Venting – Cleaned air is either recirculated or vented outside.

For laser dust collection, a well-designed system should handle both fine particulates and chemical fumes.

Choosing the Best Laser Dust Collection System

When selecting a fume extractor for CO2 laser applications, consider:

1. Airflow Capacity (CFM – Cubic Feet per Minute)

Small desktop lasers: 100–200 CFM

Industrial lasers: 500+ CFM

2. Filtration Efficiency

HEPA filters capture 99.97% of particles as small as 0.3 microns.

Activated carbon filters absorb toxic gases (e.g., formaldehyde from wood engraving).

3. Noise Levels

Look for systems with <70 dB for a quieter workspace.

4. Portability & Installation

Benchtop units for small lasers.

Centralized systems for large-scale operations.

5. Maintenance Requirements

Filter replacement frequency (some systems have washable filters).

Recommend Fume Extractor for CO2 Laser Machines

Here are some of the suitable laser dust extraction system options:

1. Dric Laser Fume Extractor Series

CFM: 350

Filtration: HEPA + Activated Carbon

Best for: Mid-sized CO2 lasers

2. POWER SPACE Laser Dust Collector

CFM: 500–1000

Filtration: Multi-stage HEPA

Best for: Industrial laser cutting

Maintenance Tips for Your Dust Extraction System

To keep your dust extraction system running efficiently:

Replace filters regularly (check manufacturer guidelines).

Clean intake vents to prevent clogging.

Inspect ductwork for leaks or blockages.

Monitor airflow – reduced suction indicates maintenance is needed.

Conclusion

A high-quality fume extractor for CO2 laser, an efficient dust extraction system, and a well-designed laser dust collection setup are critical for safety and performance. Whether you're a hobbyist or an industrial user, choosing the right system will improve air quality, extend machine life, and ensure compliance with workplace safety regulations.

For the best results, opt for a commercial-grade laser fume extractor with HEPA and activated carbon filtration.

Request Quote

Tell us your inquiry, we will recommend a suitable product model or solution for you!