This comprehensive guide will delve into the essence of fume extractor machines, their operation, types, and applications.

Why We Use Fume Extractor Machine?

Welding operations include resistance spot welding, gas shielded welding (such as MIG welding and TIG welding), as well as plasma arc welding. These welding processes produce a large amount of welding fumes, which contain metal oxides, fluorides, and other harmful particles. These substances are harmful to human health and can contaminate the working environment.

A fume extractor machine is a specialized piece of equipment designed to capture and remove harmful fumes, gases, and particulates from the air in industrial settings. These machines are critical for maintaining air quality and ensuring the health and safety of employees by reducing the risk of respiratory and other health issues associated with exposure to toxic substances.

How Does Fume Extractor Machine Work?

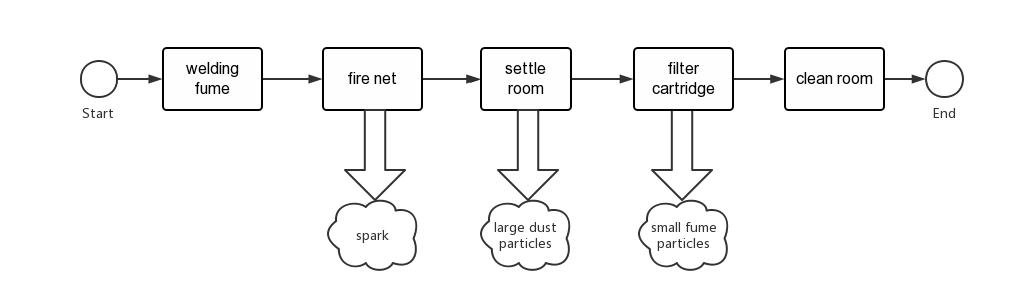

The operation of a fume extractor machine is based on a straightforward yet effective principle. Here's how it works:

Air Intake: The machine draws in contaminated air through an intake port, typically located at the front or side of the unit.

Filtration: The contaminated air passes through a series of filters, including the fume extractor filter, which trap and collect the pollutants. The primary filter, such as a HEPA filter, captures larger particles, while the fume extractor filter removes finer contaminants.

Exhaust: Once the air is filtered, it is either recirculated back into the workspace or expelled outside through an exhaust system, depending on the type of fume extractor machine.

Maintenance: Regular cleaning and replacement of the fume extractor filter and dust collector are essential to ensure the machine's continued effectiveness.

Types of Fume Extractor Machines

Fume extractor machines come in various types, each designed to meet specific industrial needs:

Movable Fume Extractor: Ideal for mobile applications, these units can be easily moved from one work area to another, providing flexibility in welding, soldering, and other tasks that generate fumes.

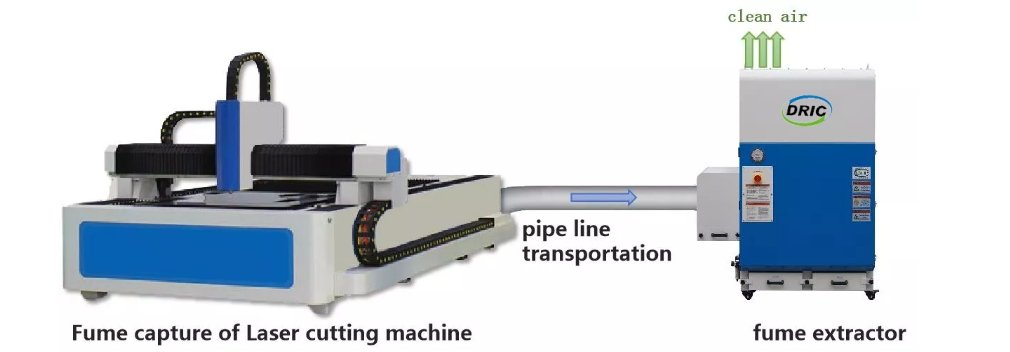

Laser Dust Collector: These machines are used in laser cutting machine, just connect the pipe. This dust collector can capture and remove dust and fume from laser cutting machine.

Fume Extractor System: Designed for heavy-duty use, these units are permanently installed in large workshops or production areas where continuous fume extraction is required. The main unit is usually installed outside, and the pipes and fume extraction torchs are connected in workshop.

Applications of Fume Extractor Machines

Fume extractor machines find extensive use across a wide range of industries and applications:

Welding: In welding operations, fume extractor machines are crucial for capturing metal fumes, gases, and particulates that can be hazardous to welders'health.

Laser Cutting: During laser cutting processes, fume extractor machines help remove smoke and fumes produced by the burning of materials.

In conclusion, the fume extractor machine is an indispensable tool for maintaining a safe and healthy industrial environment. By understanding what a fume extractor machine is, how it works, the types available, and their applications, industries can make informed decisions to protect their workforce and comply with environmental regulations. The use of a fume extractor machine, along with its integral components such as the fume extractor filter and fume extractor dust collector, is a proactive approach to dust and fume management that yields significant benefits for both employees and employers alike.

Request Quote

Tell us your inquiry, we will recommend a suitable product model or solution for you!